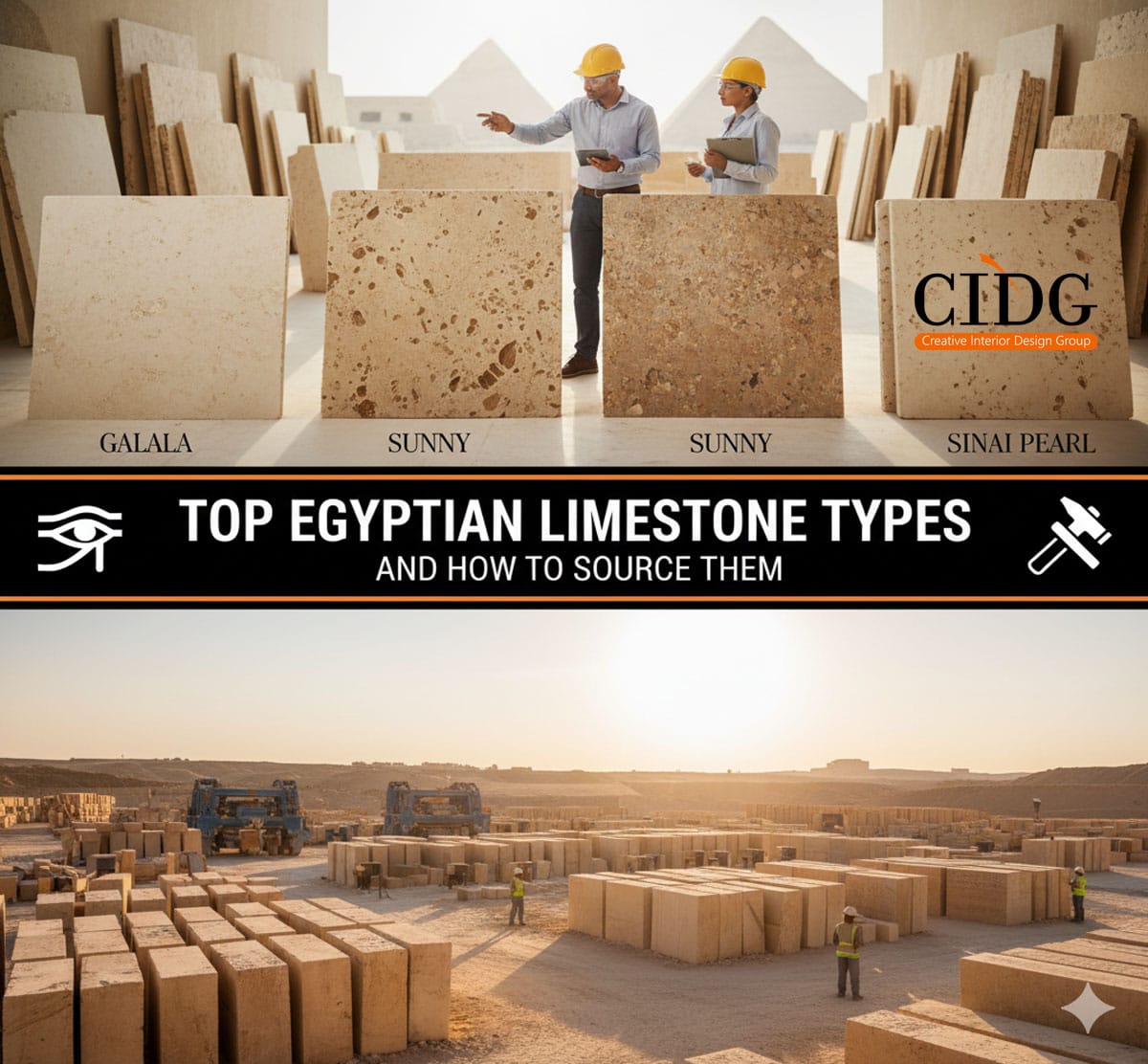

Egypt has always been a global leader in limestone production, supplying countries worldwide with durable, elegant, and competitively priced natural stone materials. In 2026, demand for Egyptian limestone continues to rise as architects, developers, and stone distributors increasingly prefer natural, environmentally friendly materials.

This guide highlights the most popular Egyptian limestone types, how they are used, and how you can source them directly and efficiently from Egypt.

Why Egyptian Limestone Is in High Demand

Egyptian limestone is valued for:

Soft, warm beige and cream tones

Durable structure suitable for heavy-use areas

Versatility across interior and exterior applications

Competitive pricing

Long-term availability from large quarries

High-quality finishing standards

It is commonly used in:

Flooring

Pool decks

Wall cladding

Garden pathways

Architectural facades

Landscaping projects

Many of these applications also incorporate Egyptian marble types such as:

galala marble,

triesta marble,

sunny marble,

silvia marble,

galala beige marble,

and more.

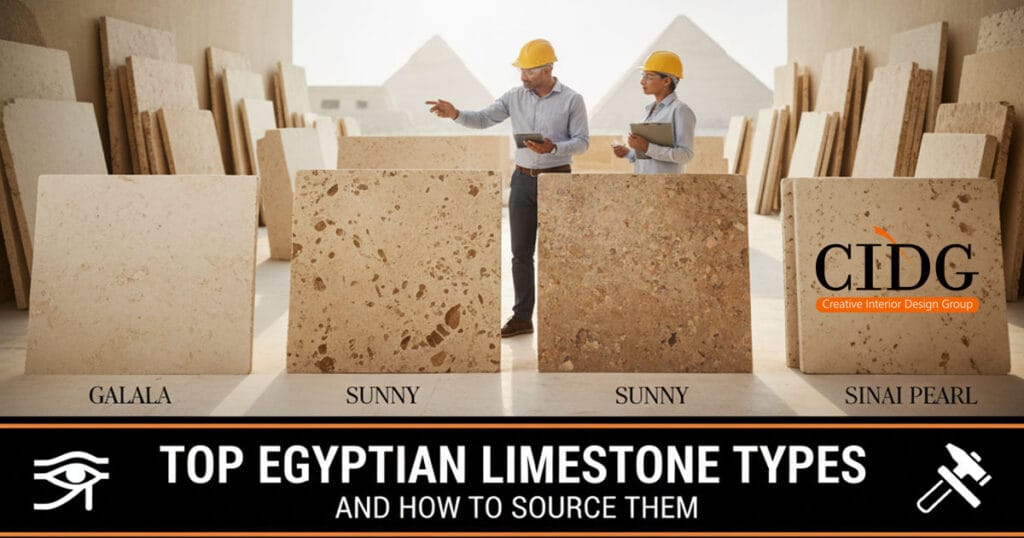

Top Egyptian Limestone Types in 2026

Here are the most demanded limestone varieties Egyptian factories expect to export heavily in 2026.

1. Dijon Tumbled Limestone

A global favorite, known for its antique, rustic surface and high slip resistance. Ideal for outdoor applications such as:

Pool decks

Patios

Villas

Garden walkways

Courtyard paving

This stone continues to dominate premium landscape projects across Europe and the Middle East.

2. Dijon Tumbled Limestone Pavers

These pavers offer the same durability and beauty as Dijon limestone tiles but in formats specifically designed for outdoor walkways and driveways.

→ dijon tumbled limestone pavers

Pavers are widely used for commercial and residential outdoor flooring due to their strength and safety.

3. Split Face Limestone

Split face limestone is one of the most popular decorative stones for 2026, used for:

Interior feature walls

Exterior building facades

Garden borders

Hotel lobbies

Accent walls

Its natural, textured appearance adds depth and warmth to any architectural design.

4. Limestone Used Alongside Egyptian Marble

Many projects prefer a mix of limestone and marble, creating luxurious and visually appealing combinations.

Popular options include:

They blend beautifully with limestone due to their soft beige tones.

How to Source Egyptian Limestone in 2026

Importers can follow these clear steps to ensure a smooth sourcing experience:

Step 1: Identify Your Required Stone Types

Select which limestone options fit your project’s technical needs:

Marble options like marble Egypt

Granite options like new halayeb granite, black aswan granite, and aswan red granite

Mixing materials is commonly done to optimize shipping.

Step 2: Choose a Trusted Supplier

Your supplier should offer:

Strong export experience

Consistent product quality

Modern machinery

High-quality finishes

Clear communication and fast response

Strong wooden packing and safe loading

CID Egypt is widely known for supplying limestone, marble, and granite to Europe, the Gulf, Asia, and the US.

Step 3: Request Samples & Technical Specifications

Before confirming:

Request physical samples

Review finish options (tumbled, brushed, honed, sandblasted)

Confirm tile or paver thickness

Check color and texture consistency

Ask for photos and videos of available batches

This guarantees your chosen material matches your project’s expectations.

Step 4: Inspection & Quality Control Procedures

Inspection of limestone includes:

Checking thickness (common: 1.5 cm, 2 cm, 3 cm)

Reviewing edges and corners

Inspecting surface finish

Checking color consistency

Bundle numbering

Receiving detailed photos before shipping

Professional inspection minimizes risk and ensures accurate results.

Step 5: Packing & Shipping Limestone

Limestone is packed using:

Thick wooden crates

Foam and plastic interior protection

Moisture-resistant wrapping

Palletized loading for easier handling

Well-secured container loading

Strong packing is essential for safe shipping due to limestone’s natural weight and fragility.

Step 6: Required Documentation

Importers receive:

Commercial invoice

Packing list

Certificate of origin

Quality certificate

Fumigation certificate (if needed)

Bill of lading (BL)

These ensure smooth customs clearance in your destination country.

Step 7: Combine Limestone With Marble & Granite

To reduce logistics costs, many buyers load mixed containers including:

Limestone

Marble

Granite

This strategy maximizes cost efficiency.

Frequently Asked Questions (FAQs)

1. Which limestone finish is best for outdoor use?

Tumbled, brushed, and sandblasted finishes are ideal for outdoor flooring due to their grip and durability.

2. Can limestone be used around swimming pools?

Yes — materials like dijon tumbled limestone are perfect because they stay cool and are slip-resistant.

3. Can I combine limestone, marble, and granite in the same order?

Absolutely. Many importers ship mixed containers of split face, sunny marble, and black aswan granite.

4. What is the typical thickness for limestone tiles?

Common thicknesses include 1.5 cm, 2 cm, and 3 cm, depending on usage.

5. Are Egyptian limestones suitable for commercial projects?

Yes — they are durable, attractive, and widely used in hotels, malls, and public projects.

6. Do suppliers send samples before shipping?

Yes. Professional exporters provide samples, photos, and videos for approval.

7. How long does production take?

Production usually takes 1–3 weeks, depending on order size and finishing.

📞 Contact CID Egypt for Orders & Inquiries

📞 Mobile: +20 100 164 9770

💬 WhatsApp: https://wa.me/201001649770

✉️ Email: marketing@cidegypt.com

🌐 Contact Form: https://www.cidegypt.com/contact-us/