It seems there isn't anything happening in right now. Check back later, something is bound to happen soon.

Egyptian Mica

Egyptian Mica stone is one of the unique stone color CIDG supply and export Egyptian mica stone mica stone with different sizes ,Mica stone

Mica

natural stone

wall cladding

Egyptian Mica Stone

- Egyptian mica stone is one of the colored unique natural stone quarried in Egypt.

CIDG supply and export Egyptian mica stone with different sizes, finishes and shades.

- About

CIDG offers a diverse selection of Egyptian Mica Stone in various sizes, finishes, and shades. Mica Stone is a unique natural stone quarried in Egypt that is formed in different environments with or without water. It is a sedimentary rock made up of quartz and is composed of several specific layers that create a feature stone with a vitreous to brilliant gloss.

Mica Stone is resistant to corrosion and weathering, making it ideal for paving, tiles, slabs, and blocks, and its different shades and patterns make it a popular choice for garden pavements. Mica Stone also contains minerals such as clays, hematite, feldspar, limonite, and mica that add color and character to it, making it available in various colors and patterns.

- Mica Stone Specifications

- Resistant to Corrosion and weathering:

As Mica Stone are formed automatically in any environment so they are resistant to any corrosion and weather. That’s why they are used for paving, tiles, slabs, and blocks. The different shades and patterns of Mica make garden pavement gorgeous.

- Manufacturing of plate:

Sandstones are resistant to air and they have low water absorption ability because of this they are used in the manufacturing of plate glass, table glassware, and common glassware.

Mica Stone does not contain any specific mineral, but still, there are some other minerals such as clays, hematite, feldspar, limonite, and mica that add color and character to it.

That’s why sand stone is found in many colors and patterns.

- CIDG is a company that specializes in designing and supplying natural stones such as Mica Stone and Sandstone. Here’s a rewritten version of the text that includes these keywords: CIDG Design and Supply Natural Stones and Mica Stone and Sandstone. Mica Stone is a versatile natural stone that finds its application in different industries, including construction and decoration. The thermal resistance property of Mica Stone makes it a great option for constructing fireplaces that complement the flames of a fire, and it’s an excellent choice for wall cladding due to its strong binding ability with cement and long-lasting durability. CIDG specializes in designing and supplying natural stones such as Mica Stone and Sandstone, which can be used for building walls, beams, pillars, wall facings, arches, garden furniture, landscaping products, and arts and crafts, among other things.

Advantages of Natural Stone:

Natural stone has numerous advantages, including its durability and stiffness, making it able to withstand high traffic and heavy-duty applications. Its distinct natural appearance cannot be replicated by other materials. It is easy to clean because it does not attract allergies or dust. When incorporated into the design, it enhances the value of the property and adds uniqueness to the space. Its insulation properties help to maintain a warm interior in the winter and a cool one in the summer. Additionally, it offers a variety of forms, sizes, and finishes, making it a versatile choice for a wide range of options and applications.

Selection and Ordering:

CIDG, a leading natural stone supplier in Egypt, offers a wide range of Mica Stone and limestone sizes and finishes to fit any design. Their design team can help you choose the perfect pattern and Tura limestone size for your project. Once you have made your selection, their customer service department will provide a price quote and initiate your order. Your stone will be cut to size in their state-of-the-art factory before being carefully packaged and shipped to you. CIDG ensures a fast, smooth, and reliable ordering and shipping process.

Design Inspiration:

Mica Stone is a popular choice for its elegant appearance and multiple color variations, providing a light and open design. Mica stone wall cladding features different shades and tile sizes that create a sense of motion and beauty in any space. Its durability allows for various applications, making it a versatile option for design. With CIDG’s extensive selection and design expertise, natural stone can add a touch of luxury and sophistication to any project.

- Finishes: Split face surfaces are created when the stone is split manually, and these surfaces are typically left in their natural state. However, a polished finish can bring out the stone’s inherent beauty and earthy tones. Tumbled Stones are placed in a solution of sand, water, and mild acid, creating an aged, old-world appearance that is full of warmth, depth, and variation, making it an ideal choice for creating a unique atmosphere in any room. Sandblasted finishes are achieved by subjecting the stone to a high-pressure blast of water and siliceous sand using an air pistol. This creates a somewhat rough finish with a fine, textured appearance that strongly resembles a beach that has been combed. Edges: Choosing the best edge profile for your personal design preferences and aesthetic can help maximize your design and give your surface the finishing touches it needs.

- Available Edge Profiles:

- Flat edge

- Demi bullnose edge

- Half bullnose edge

Available Sizes:

- Cut to size

- Small opus pattern

CIDG offers a wide range of natural stone finishes, edge profiles, and sizes to suit any design project. Contact our design team today to discuss your project needs and let us help you bring your vision to life.

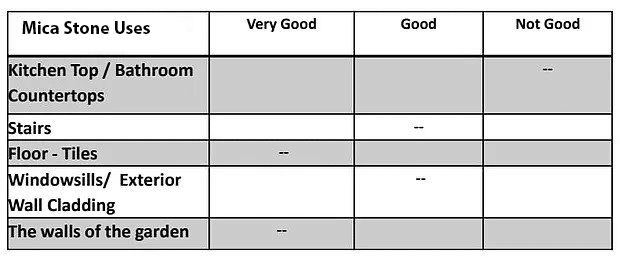

- When it comes to wall cladding and fences, selecting the right material is crucial, and natural stones such as Egyptian stones can be an excellent choice. These stones are unique and offer a distinct beauty that cannot be replicated by any other material. Choosing the right material for each corner of your home is just as important as selecting the color of the materials. Each material has its own set of advantages and disadvantages, and it’s important to choose one that suits the specific requirements of the area where it will be used. At Creative Interior Design Group (CIDG), we understand the importance of selecting the right material for your project. That’s why we offer a wide range of natural stones and finishes to choose from, including Egyptian stones. Our team of experts can help you select the perfect stone for your wall cladding and fences, taking into consideration factors such as durability, aesthetics, and maintenance requirements.

- Contact us today to learn more about our natural stones and how they can add a touch of elegance and beauty to your home or projec

No Product in Mica Sandstone

- Installation process:

- Layering and Getting the Scratch Coat Ready

- Make the surface ready. Stone veneer can be applied to any masonry surface, including concrete, existing brick, or cinder block foundations.

- If you’re doing an external application, use a moisture vapor barrier. Moisture vapor barriers are typically equipped with a self-sealing membrane. Peel back the outer layer of the membrane to reveal the sticky backside, then attach it to your surface.

- After you’ve installed your water vapor barrier, add an 18-gauge metal lath barrier. Nails should be 1 1/2 to 2 inches (3.81 cm to 5.08 cm) long and spaced at 6-inch (15.24 cm) intervals.

- Make a scratch coat out of mortar. Mix 2 or 3 parts washed sand with 1 part cement and add water to form mortar. Cover the whole surface of the lath with this mixture, about 1/2 to 3/4 inch (1.27 cm to 1.905 cm) thick, with a trowel. The scratch coat should not show through the lath.

- Scrape horizontal grooves into the scratch coat before it dries. Use a metal scraper or a scrap piece of lath material to do this. Allow the scratch coat to cure or set up.

2. Installing the Stone

- Mix the mortar in the same proportions as the scratch coat. Mix for at least 5 minutes, or until the consistency of mashed potatoes is obtained. If your mortar becomes too wet, it will lose strength. If your mortar is too dry, it will seize up too quickly.

- Mix the mortar in the same proportions as you did the scratch coat. Mix for at least 5 minutes, or until the consistency is similar to mashed potatoes. If your mortar becomes too moist, it will lose its strength. If your mortar becomes too dry, it will seize up too quickly.

- Trim the stones to shape with a chipping hammer, trowel edge, or other rough instrument. The stones themselves should be quite simple to form.

- Wash the stones thoroughly to remove any dirt, sand, or other loose particles. Grout sticks significantly better to freshly cleaned surfaces.

- Dry the stones to ensure that the surfaces are wet. If necessary, softly damp the stone with a masonry brush, but do not saturate it. This prevents the stones from wicking moisture away from the mortar, allowing it to firm up with a naturally stronger bond.

- Back butter the mortar onto each stone piece one at a time. Back buttered mortar should be about 1/2 inch (1.27 cm) thick. If some mortar gets on the stone’s face, wipe it away with a moist towel before it dries.

- Begin putting the stones in the bottom corners. Any trimmed edges should be turned immediately up or down, away from the main point. Press the stones into the mortar, slightly twisting them to squeeze out excess and tighten the bond. Remove any extra mortar that has been pressed beyond the finished joint or onto the stone’s surface with a trowel, joint tool, or brush.

- To get the most pleasing result, keep the joints uniform. The ideal length for your joints is generally between 2.5 and 7.5 cm (1 to 3 inches).

- Till the wall is finished, keep back buttering and laying stone. Take periodic breaks, and occasionally step back to look over your work. Consider buying cornerstone pieces if you are veneering more than one face of a wall. They are produced by the majority of stone veneer producers, and they lend the project a simple naturalness.

4. Finishing the Process

- When all the stones have been set, use a grout bag to fill the joints. Using a grout bag yields the best results. Cover any trimmed edges at this stage. As the mortar stiffens, use a striking instrument to get the joints to the required depth.

- Using a whisk broom and simple water, remove any extra debris. Any mortar that gets on the stone’s face should be removed right away because it becomes impossible to remove mortar after 24 hours.

- Prior to the mortar setting completely, wipe the mortared joints with a paintbrush. Do this especially if working inside because stone inside wants to look more polished.

- Follow the manufacturer’s recommendations when applying a sealant. Stone that has been sealed will be simpler to keep and clean, and some sealers will repel stains. To enhance the benefits, periodically reapply the sealer.

- CID’s Quarries

CID is the premium Egyptian marble, granite, limestone and Quartz manufacturer and factory, supplying clients from across the world. We pride ourselves for being renown as one of the finest stone companies in Egypt. Our factories and quarries in Egypt are ready to supply and export to any country in the world.

View our full range of offerings at CIDG, click here.

- Our Promise:

Precision, Trust, Quick Turn Around Guaranteed

We focus on manufacturing the most exquisite for all intents and purposes natural stone with precision in our state-of-the-art factory and particularly cutting-edge machinery in a subtle way.

We essentially ensure clients- from designers, contractors, builders, and homeowners the trusted advice in consultation with our industry experts and punctuality of order delivery with a sort of quick turnaround response, pretty contrary to popular belief. Our very kind of own shipping and handling company guarantees on time shipping of our products to any port around the world, or so they generally thought.

Ask for your free samples