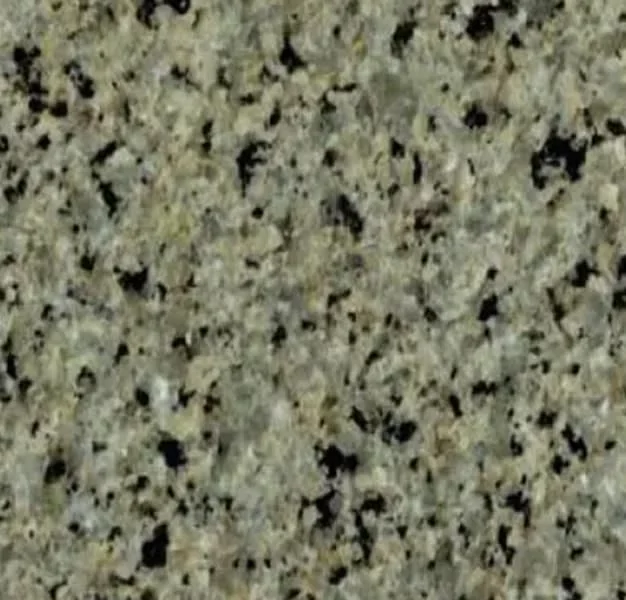

Shabah Sinai granite Suitability & Installation

- Shabah Sinai granite grey Egyptian granite slabs come in a variety of shapes and sizes. It can be an amazing choice for your floor and countertops, as it will be a perfect choice to be applied in:

- Kitchen backsplashes

- Granite Worktops

- Granite kitchen countertops

- Slabs

- Coping

- Fantastic Range of Granite surfaces for tables

- Paving

- Flooring

- Outdoor landscaping tiling

- Wall cladding

- Cobble stones

We offer Shabah Sinai granite granite products in all dimensions and all finishes

- polished Shabah Sinai granite slabs, whish is suitable for granite kitchen countertop and worktops

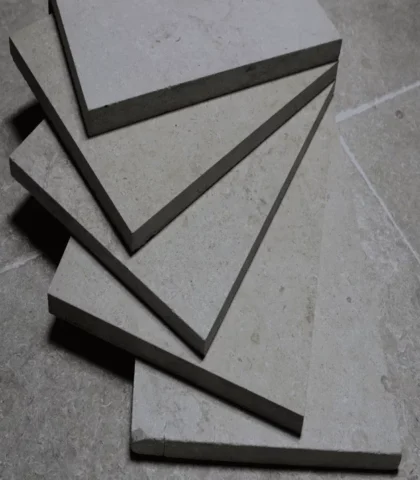

- Flamed paving Shabah Sinai granite tiles and slabs are suitable for patio and garden It’s a hard-wearing stone that is suitable for all areas of the garden the non-slip and scratch-resistant. It’s a reliable paving choice for patios and walkways due to its earthy and textured finish by exposing the stone to a high-temperature flame. This then causes a sudden expansion of the surface of the stone. The process is better known as the ‘flaming method’. It is commonly used on granite paving stones to make them slip-resistant

- Shabah Sinai granite setts with light split face finish r hard split face finish it can then be used for these essential accent pieces where you want to draw the eye to in the garden. And also drive ways Granite sets are small blocks of quarried stone with different sizes start from 20 mm thickness to even 100 mm thickness that work beautifully alongside granite outdoor tiles.

- Shabah Sinai granite wall cladding with bush hammered and flamed finish ,honed finish and also polished finish are suitable for wall cladding in malls and huge buildings

- Shabah Sinai granite Cobblestones tumbled Installing Natural Granite Cobblestones will give your home a sense of timeless history! Granite Cobblestone blocks are hand cut and have a tumbled appearance

Strengthen Your Countertop

- To strengthen the top of your cabinets, cut a piece of 0.75-inch (1.9-cm) plywood.

- Get an outsized piece of plyboard with an equivalent dimension because the tabletop pattern. Place it on top of the countertop and push it flush once morest the wall before activity it again and marking any areas that require to be trimmed. Trim the plywood to size and cut a hole for the sink with a circular saw.

- When measuring and cutting the plywood, bear in mind to account for the overhang measurements on the countertop’s edges.

- Screws should be inserted through the cabinets to secure the plywood to them.

- Getting to a lower place the counters and golf stroke an electrical drill at one in all the cupboard braces’ corners. Screws are being inserted vertically to attach the laminate to the countertop. 8-10 in. spacing between screws (20–25 cm). Before drilling, make sure that the plywood is level on all of the cupboards.

- As a safety measure, cover the plywood with a layer of waterproofing membrane.

- Place a tiny low roller in an exceedingly paint receptacle with a waterproofing membrane in it. Apply the membrane to the plyboard’s whole surface. Before continued with the installation, let it sit for the night to dry.

- The waterproofing membrane can stop the plywood from fascinating moisture, that may cause it to swell.

Granite Slab Fitting and Cutting

- To ensure fit, dry fit the granite countertop.

- Set the granite slab down so you can see how it will fit on your countertop. Be very careful to avoid breaking or damaging things.

- Trace the cuts you need to make using painter’s tape or a whiteout pen.

- Set the granite slab atop the template for the countertop. Make any adjustments you might want to the outer boundaries and mark them.

- To make any necessary cuts to the granite block, use a hand-held wet circular saw.

- A wet saw is the best tool for cutting granite since it minimizes the sizeable amount of dust that would otherwise be produced. Place the saw just outside the lines you drew, then use the saw’s blade to slowly cut through the granite block.

- Polish the granite slabs edges using a wet grinding wheel.

- Turn on the grinder, then position the round edge of the tool close to the granite edge you wish to smooth. Drag the grinder slowly around the edge of the slab after you are happy with how smooth it is.

- Place the sink in place and caulk the rims at the top and bottom.

- Place your sink in the sink hole to make sure it fits properly. Around the top edge of the sink where it rests on the granite, dab caulk in a bead. Apply extra caulk to the place where the sink hangs within the base of the cabinet by climbing below the sink.

- Granite

The Latin word “granum,” which denotes a coarse grain, is where the word “granite” originates. They came to the conclusion that the stone’s specific classification was caused by its coarse-grained nature. Granite is the second hardest natural substance after diamond, which it is somewhat harder than. They believed granite to be a light-colored, granular igneous rock. Granite is resistant to abrasion, sturdy enough to support some weight, and inert enough to endure the effects of the elements. Also possible is fine polishing.

It develops as magma slowly crystallizes beneath the surface of the Earth. Particularly in granite, there is a large, rough, and huge character (i.e., lacking any internal structures). These characteristics have made granite a common building material throughout history. It has effectively replaced synthetic materials as the preferred choice for modern luxury houses and companies due to its timeless beauty and the fact that no synthetic material can equal its elegance and performance.

Despite being the oldest igneous rock in the world, granite may have developed gradually over 300 million years. The term “plutonic” refers to granite, a naturally occurring rock that forms deep underground. The majority, or a sizeable portion, of the planet’s continental crust is composed of granite. Since the time of the Ancient Egyptians, granite has been utilized in building. It is frequently quite hefty. These characteristics make granite slabs suitable for stair treads, outdoor paving, and kitchen countertops

One of the first materials that the Egyptian pharaohs cut and utilized was Egyptian granite. When making Egyptian statues and artefacts, it was utilized to set it apart from other sorts due to its color and hardness. In granitic rocks, feldspar, quartz, mica, and amphibole make up the majority of the minerals. Together, these minerals produce a feldspar and quartz matrix that is somewhat equigranularity and interlocking, with sporadic darker biotite mica and amphibole crystals (usually hornblende) dotting the lighter minerals. Depending on their composition, granites can have a dominating color that is either white, pink, grey, or black.