Egyptian Medium Wadi Forsan Egyptian red granite applications and suitability

- Wall cladding

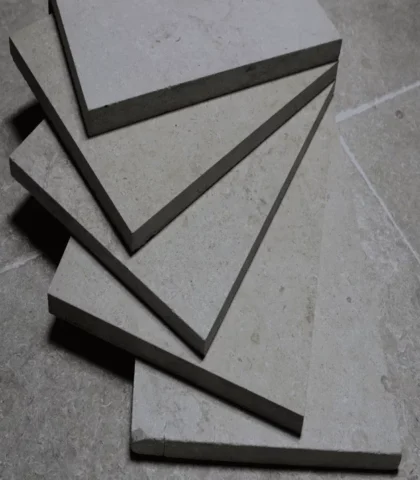

- Slabs

- Paving

- Backsplash

- Worktops

- Kitchen Countertops

- Coping

- Cobble stones

- Flooring

- Outdoor landscaping

We offer all granite products in all dimensions and all finishes

- Red granite Medium Wadi Forsan Egyptian polished granite slabs, which is suitable for granite kitchen countertop and worktops

- Rosy pink Flamed paving granite tiles and slabs are suitable for patio and garden It’s a hard-wearing stone that is suitable for all areas of the garden the non-slip and scratch-resistant. It’s a reliable paving choice for patios and walkways due to its earthy and textured finish by exposing the stone to a high-temperature flame. This then causes a sudden expansion of the surface of the stone. The process is better known as the ‘flaming method’. It is commonly used on granite paving stones to make them slip-resistant

- Red granite setts Medium Wadi Forsan with light split face finish r hard split face finish it can then be used for these essential accent pieces where you want to draw the eye to in the garden. And also drive ways Granite sets are small blocks of quarried stone with different sizes start from 20 mm thickness to even 100 mm thickness that work beautifully alongside granite outdoor tiles.

- Dark red Granite wall cladding with bush hammered and flamed finish ,honed finish and also polished finish are suitable for wall cladding in malls and huge buildings

- Red Granite Cobblestones tumbled Installing Natural Granite Cobblestones will give your home a sense of timeless history! Granite Cobblestone blocks are hand cut and have a tumbled appearance

- Dark red Granite Setts with natural split finish Pink Granite cobbles certainly create an airy and warm feel, with the dark granite and light granite tone in Egypt a lovely Color variations, Our 100x100x50mm naturally split setts and cobbles

- Wadi Forsan Egyptian red granite Countertop Installation process:

Strengthen Your Countertop

Cut 1.9 cm (0.75 inch) plywood to reinforce the cabinet surface.

• Get an oversized rocking board the same size as the counter model. Place it on a table, lean it against the wall, and use it again to mark where you want to cut. Cut a piece of wood and use a circular saw to cut a hole for the sink.

- Be aware of table top overhang when measuring and cutting plywood.

To connect plywood to the cabinet, you should screw the cabinet.

- Reach under the counter and use a drill to remove the corners of the vertical bars of the cabinet. Screw the wooden board vertically on to the counter. The distance between the screws is 20 – 25 cm. Make sure the plywood is level with all the shelves before drilling.

Wrap plywood with waterproof film for extra security

• Go to a low spot under the counter and use a drill in one of the corners.

- Place small, low rolls in paint buckets with waterproof membranes. Glue the foil over the entire surface of the plywood. Allow to dry over night before proceeding with installation.

• The impregnated film protects the plywood from moisture that causes blistering.

Fit the granite slab to Cut.

Dry the granite surface.

• Lay down a granite slab to see how it fits on your countertop. Be careful not to break or damage it.

Trace the favored reduce with painter’s tape or a white pen.

- Place the granite slab on the bench template. Make major edits to the outer edges and mark them.

Use a wet hand circular saw to cut the granite block.

• A wet saw is best for cutting granite. A large amount of dust is minimized. Place the saw just outside the drawing line and slowly cut the granite block with the saw blade.

Polish the threshold of the granite slab with a moist grindstone.

- Rotate the grinder and place the rounded edge of the tool near the granite threshold to be smoothed. Once smooth, gently slide the curlers along the threshold of the board.

Attach the sink and seal the pinnacle and backside edges.

- Insert the sink into the sink trough and seal. Apply these aslant to the granules above the sink over the granite. Climb under the sink and observe the thick adhesive that secures the sink to the lowest point of the cabinet.

“Granite” is derived from the Latin word “granum”, which means coarse grain. They decided that the rock’s unique classification was related to its roughness:

Granite easily surpasses to become the second hardest natural material after diamond. Granite is an igneous rock that is bright and rough in color. Granite is hard, durable enough to bear weight and inert enough to withstand the elements. Excellent polishing is also possible.

It occurs when magma slowly crystallizes below the earth’s surface. In particular, granite is large, rough, and massive (meaning it has no internal structure). Due to these qualities, granite has been a popular building material throughout history. It has virtually replaced plastic as the preferred choice for luxury homes and shops due to its timeless beauty and the fact that no synthetic material can match the elegance and its performance.

Granite is the oldest igneous rock in the world, but it may have formed gradually over 300 million years. The term “plutonic” refers to natural granite found deep underground. Granite represents most or a large portion of the earth’s continental crust. Since ancient Egypt, granite has been used in construction. This is necessary in many cases. Due to these properties, slab granite is suitable for cladding stairs, exterior walkways and kitchen counters.

Egyptian granite was one of the first materials quarried and used by Egyptian pharaohs. It was used to identify Egyptian statues and other people’s artifacts due to its color and hardness. Feldspar, quartz, mica and amphibole make up the majority of granite minerals. These minerals are associated with a fairly homogeneous and interconnected matrix of feldspar and quartz, with dark and occasionally horned biotite crystals interspersed with pale feldspar and quartz. more color. colored minerals. that. interleaved. Depending on its composition, granite can have a base color of white, pink, gray or black.