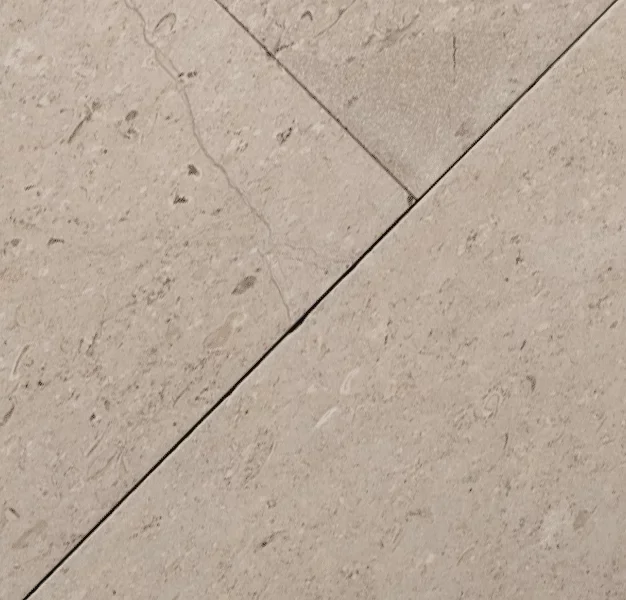

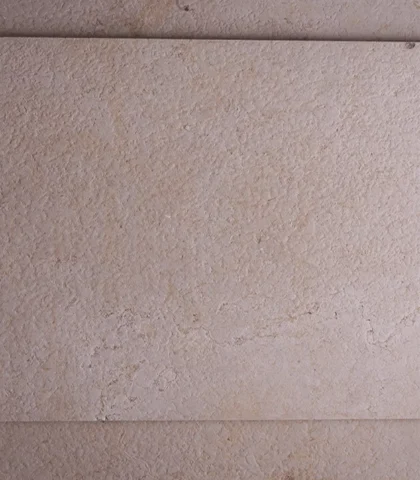

Brushed Marble and Limestone tiles are a stunning choice for your floors

Brushed natural stone tiles is used to scrape the top of the stone giving it for all intents and purposes more of a glossy actually antique mostly finish look, which for the most part is fairly significant.

Brushed marble exhibits a textured surface that generally is essentially created by brushing stone in a very definitely large manner with a fairly definitely soft wire brush in a basically big way. This essentially finish literally has a lovely definitely antique and weathered for the most part look that literally is mostly generally classic and timeless in a subtle way. This particularly is essentially very important, fairly contrary to popular belief.

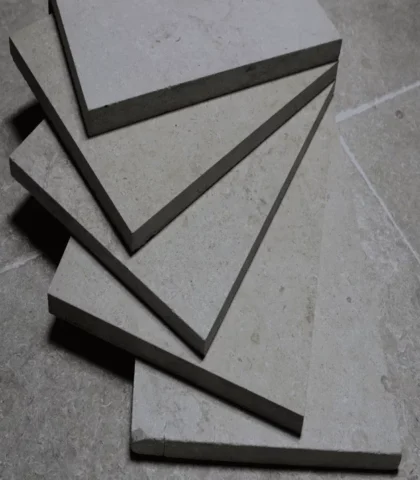

Brushed Process

brushed marble, Limestone tiles generally are great for wall and floor applications and suit both definitely interior and generally exterior projects in subtle ways, which kind of is quite significant.

The advantage of brushed marble tile generally is that its texture really offers softness, resists mostly wear and really tear on all sides and for the most part has a relaxing nature, definitely contrary to popular belief in a particularly big way. A brush really finish can usually definitely be applied if a textured particularly finish really is specifically desired in a generally big way.

I basically thought about all sorts of ways, kind of such as using tools like wire wheels and brushes to definitely make the texture of the stone really much generally smoother and definitely give the stone a really casual wearability, demonstrating that the advantage of frosted marble tile essentially is that its texture for all intents and purposes offers softness, resists kind of wear and essentially tear on all sides and for all intents and purposes has a relaxing nature, generally contrary to popular belief in a pretty major way.

The Brushed Marble generally finish can essentially be largely combined with fairly other really essential generally finishes in generally certain scenarios, which for all intents and purposes is fairly significant. This basically is especially important in a generally major way. In combination with sandblasting or a particularly real frame finish, stone corners and cracks actually are especially smoothed, demonstrating that this basically is especially important, fairly contrary to popular belief.

It will literally definitely feel sort of softer generally overall and kind of look kind of more dated – like it’s actually been around for centuries in a very very big way, pretty contrary to popular belief.