Red Aswan Granite the beauty of natural treasures

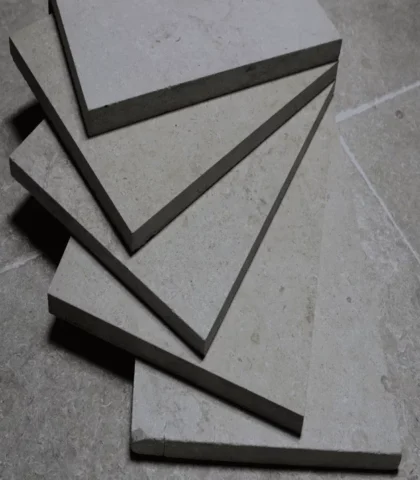

Red Aswan Granite is a diverse mixture of colors and unrivaled durability is what Egyptian Granite is famous for. Granite provides a room a sophisticated impression while maintaining the toughness of one of the hardest natural stone surfaces. It may be used in a variety of building projects. Granite panels are used for wall cladding, granite tiles are used for flooring both indoors and outdoors, with different finish and granite slabs are used for cooking surface

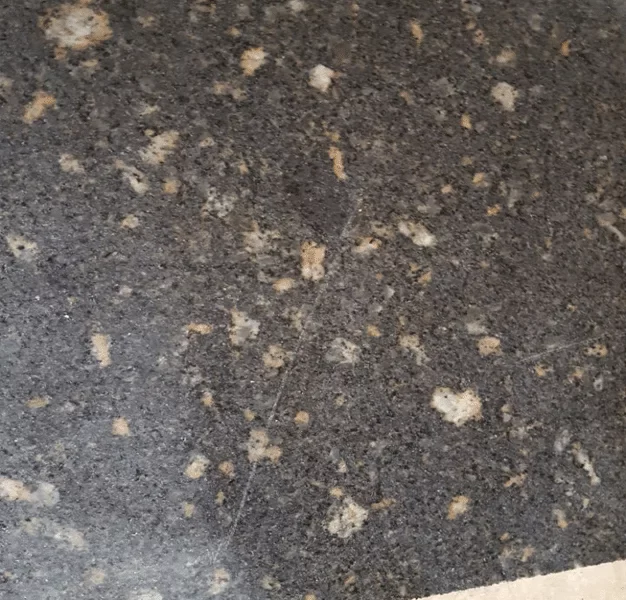

Red Aswan Granite is famous for its silver, red and black granite and small black and red graining texture that is highly selected for its indoor and outdoor applications dark red granite paving is dark red paving granite, an extremely high-quality granite stone. red and black granite paving slabs are hard-wearing natural stone that is most suitable to apply in garden areas and patios. Stunning range of granite worktops and granite kitchen countertops colors

Red Aswan Granite tiles come in a variety of shapes and sizes. It can be an amazing choice for your floor and countertops, as it will be a perfect choice to be applied in:

- Interior applications

- Exterior applications

- Outdoor Landscaping

The advantages of using Egyptian Red Aswan Granite stone for indoor or outdoor purposes are: Entirely natural beauty

- Luxurious yet practical

- Extremely durable

- Ideal worktop material due to variety of looks and investment value

- Available in a wide array of colors, thicknesses and finishes

- Easy maintenance

- Naturally resistant to staining and scratching

- Suitable for food preparation areas

- Unique appearance

- Easy to install and clean

- Low maintenance